Inventory Optimization Solutions for Modern-day Businesses

Contact Us

Improved Demand Forecasting

Predict future demands with greater precision by leveraging the power of historical data, market trends, and advanced analytics

Minimize holding cost

Avoid stockouts and excess inventory

Meet customer expectations

Real-time Inventory Visibility

Our inventory management solutions empower enterprises to maximize profits and minimize risks with real-time traceability

Keep a tab on inventory levels

Reduce obsolescence costs

Optimized inventory replenishment

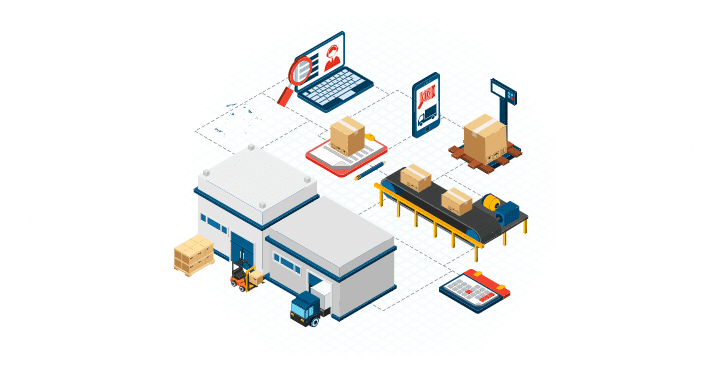

Inventory Optimization for Operational Excellence

With markets becoming increasingly dynamic, customer expectations soaring, and supply chains growing more complex, businesses must adapt and streamline their inventory management processes. The meticulous effort to ensure that businesses hold the right inventory levels to meet the demand of their customers at the right time is paramount to avoiding unnecessary storage costs associated with overstocking.

Complexities in the MRO Inventory Management Process

Inventory management is indeed one of the most important and difficult segments of MRO supply chain management, which keeps businesses on edge. From unpredictable demand fluctuations to the ever-present threat of stockouts, there’s no shortage of challenges that can throw a wrench in your supply chain.

Overstocking

Wasted space, tied-up capital, and obsolescence risk.

Understocking

Lost sales, frustrated customers, and damaged reputations.

Demand Forecasting Woes

Difficulty predicting future needs due to external factors.

Inaccuracy & Inefficiency

Manual processes are prone to errors and have limited visibility.

Evolving Landscape

Adapting to changing preferences, technologies, and competition.

Transforming Inventory Management Challenges into Opportunities with Moglix Solutions

Moglix Business simplifies and optimizes the inventory management process with Vendor-Managed Inventory (VMI). VMI’s efficiency enhancement is evident as it allows suppliers to proactively monitor and replenish stock based on real-time analytics.

How Vendor-Managed Inventory (VMI) Works?

Agreement

Supplier and buyer agree on a VMI program outline, including product selection, restocking levels, and communication channels.

Data Sharing

Buyer shares real-time sales and inventory insights with the supplier through an inventory management platform.

Order Generation

Based on the analytics data and agreed-upon levels, a purchase order is generated.

Delivery

The supplier ships the required inventory to the buyer, maintaining optimal stock levels.

Monitoring

Both parties continuously monitor inventory levels and sales data, adjusting the program as needed.

Benefits of Vendor-Managed Inventory

Reduced Costs

Businesses can scale to negotiate better pricing with suppliers, leading to cost savings on procurement and storage.

Improved Efficiency

Single window procurement of MRO items enables organizations to save time and reduce the complexities associated with multiple suppliers and transactions.

Enhanced Accuracy

Ensure accurate stock levels and order fulfillment with analytics to minimize the risk of stockouts and overstocking.

Minimized Risk

Tackle challenges such as demand fluctuations, obsolescence, and damage, allowing to focus on core business activities.

Increased Visibility

Gain real-time insights into inventory levels across all locations to make data-driven decisions about MRO items.

Improved Customer Satisfaction

Enterprises can significantly improve their customer satisfaction and loyalty with consistent product availability and timely order fulfillment.

Strong Partnerships

With a shared platform, suppliers and customers can efficiently coordinate and align their operations.

FAQs

- Inventory management takes a broader view of your stock, encompassing all locations (warehouses, stores, etc.) and focusing on overall quantity and value. It involves tasks like forecasting demand, setting reorder points, and optimizing stock levels across the entire supply chain. Warehouse inventory management zooms in on the specifics within a warehouse. It tracks individual items, their locations, and movement within the facility. It handles tasks like picking, packing, and shipping, ensuring efficient order fulfillment.

- Effective inventory management is the backbone of a smoothly running supply chain. The importance of inventory management is highly emphasized as it:

- Ensures enough stock to meet customer demand, avoiding lost sales and frustrated customers.

- Minimizes overstocking, which ties up capital and incurs storage fees.

- Streamlines order processing and fulfillment, leading to faster delivery times.

- Maintains consistent product availability status and builds trust and loyalty.

- Balances inventory levels with working capital needs, allowing for better financial flexibility.

- Efficient inventory management significantly impacts working capital by optimizing cash flow. Minimizing excess stock reduces holding costs, freeing up capital for crucial operational needs. Conversely, avoiding stock outs through accurate forecasting ensures uninterrupted operations and customer satisfaction.

- Vendor-Managed Inventory (VMI) is a collaborative approach to inventory optimization where the supplier takes an active role in monitoring and managing the customer's inventory levels. In a VMI system, the supplier is responsible for ensuring that the customer has the right amount of stock at the right time. The supplier often has access to real-time data and uses it to make decisions about when to replenish stock, minimizing stockouts and excess inventory.

- By choosing Moglix inventory optimization software, businesses gain a comprehensive solution that empowers them to:

- Gain real-time inventory insights

- Perform better demand forecasting

- Enable vendor-managed inventory

- Leverage data automation